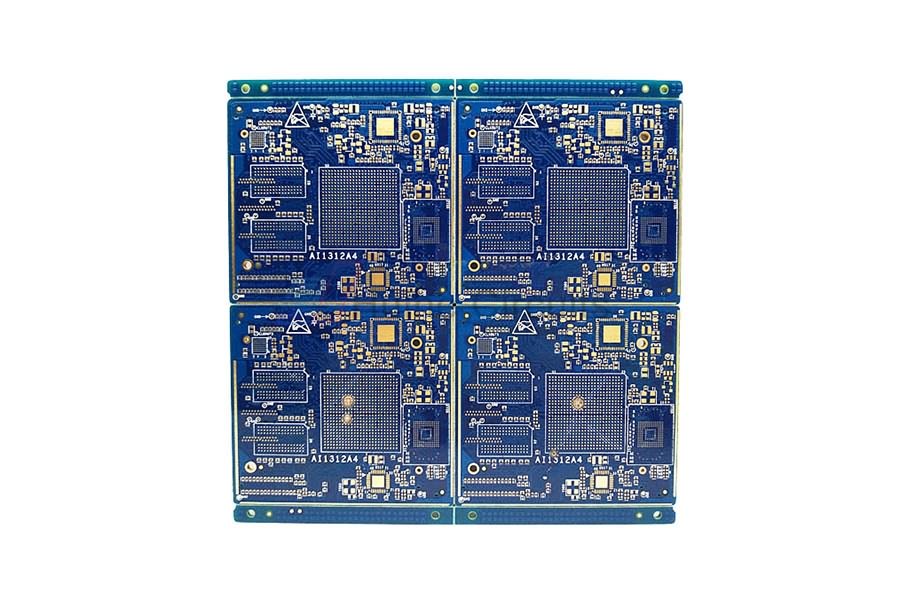

4 Txheej ENIG Impedance Tswj Hnyav tooj liab PCB

Kev Ceeb Toom Txog Kev Tsim Kho Engineering Ntawm Hnyav Copper PCB

Nrog txoj kev loj hlob ntawm cov cuab yeej siv hluav taws xob, qhov ntim ntawm PCB ntau dua thiab me me, qhov ceev yog ntau thiab ntau dua, thiab cov txheej txheem PCB nce, yog li ntawd, yuav tsum muaj PCB ntawm cov txheej txheem sib xws, muaj peev xwm tiv thaiv kev cuam tshuam, txheej txheem thiab kev tsim khoom xav tau ntau dua. thiab siab dua, raws li cov ntsiab lus ntawm engineering tsim ntau heev, feem ntau yog rau hnyav tooj liab PCB manufacturability, khoom siv tes ua haujlwm thiab kev ntseeg siab ntawm cov khoom tsim engineering, nws yuav tsum paub txog tus qauv tsim thiab ua tau raws li qhov yuav tsum tau ua ntawm cov txheej txheem ntau lawm, ua tus tsim. khoom smoothly.

1. Txhim kho lub uniformity thiab symmetry ntawm puab txheej tooj liab nteg

(1) Vim tias cov nyhuv superposition ntawm cov txheej txheej sab hauv thiab cov kev txwv ntawm cov dej ntws, cov tooj liab hnyav PCB yuav thicker nyob rau hauv cheeb tsam nrog cov seem tooj liab ntau dua li ntawm thaj chaw uas tsis tshua muaj tooj liab seem tom qab lamination, ua rau tsis sib xws. thickness ntawm lub phaj thiab cuam tshuam rau tom qab thaj thiab sib dhos.

(2) Vim tias qhov hnyav tooj liab PCB yog tuab, CTE ntawm tooj liab txawv heev ntawm cov substrate, thiab qhov sib txawv deformation yog loj tom qab siab thiab kub.Lub puab txheej ntawm tooj liab faib tsis yog symmetrical, thiab warpage ntawm cov khoom yog yooj yim tshwm sim.

Cov teeb meem saum toj no yuav tsum tau ua kom zoo dua hauv kev tsim cov khoom, nyob rau hauv qhov chaw tsis cuam tshuam rau kev ua haujlwm thiab kev ua haujlwm ntawm cov khoom, txheej txheej sab hauv ntawm qhov chaw tsis muaj tooj liab kom deb li deb tau.Tus tsim ntawm tooj liab taw tes thiab tooj liab thaiv, los yog hloov qhov loj ntawm tooj liab nto rau tooj liab taw tes nteg, optimize lub routing, ua kom nws ceev uniform, zoo sib xws, ua rau tag nrho cov layout ntawm lub rooj tsavxwm symmetrical thiab zoo nkauj.

2. Txhim kho cov tooj liab seem ntawm cov txheej sab hauv

Nrog rau qhov nce ntawm tooj liab thickness, qhov sib txawv ntawm txoj kab sib sib zog nqus.Nyob rau hauv cov ntaub ntawv ntawm tib tooj liab residual tus nqi, tus nqi ntawm cov resin filling yuav tsum tau nce, yog li nws yog tsim nyog los siv ntau yam semi-kho nplooj ntawv kom tau raws li cov kua nplaum filling.Thaum cov resin tsawg dua, nws yog ib qho yooj yim uas yuav ua rau tsis muaj kua nplaum lamination thiab uniformity ntawm lub thickness ntawm lub phaj.

Tus nqi qis qis qis yuav tsum muaj ntau ntawm cov resin sau, thiab cov resin txav tau tsawg.Nyob rau hauv qhov kev txiav txim ntawm lub siab, lub thickness ntawm dielectric txheej nruab nrab ntawm cov tooj liab daim ntawv cheeb tsam, lub cheeb tsam kab thiab substrate cheeb tsam muaj ib tug zoo sib txawv (lub thickness ntawm dielectric txheej ntawm cov kab yog lub thinnest), uas yog ib qho yooj yim mus ua. qhov ua tsis tiav ntawm HI-POT.

Yog li ntawd, tus nqi tooj liab residual yuav tsum tau txhim kho kom ntau li ntau tau nyob rau hauv kev tsim ntawm hnyav tooj liab PCB engineering, thiaj li yuav txo tau qhov yuav tsum tau rau kua nplaum filling, txo qhov kev cia siab ntawm cov kua nplaum filling tsis txaus siab thiab nyias txheej nruab nrab.Piv txwv li, cov ntsiab lus tooj liab thiab tooj liab thaiv tsim tau muab tso rau hauv thaj chaw tsis muaj tooj liab.

3. Nce kab dav thiab kab sib nrug

Rau hnyav tooj liab PCBs, ua rau txoj kab dav dav tsis tsuas yog pab txo qhov nyuaj ntawm kev ua etching, tab sis kuj muaj kev txhim kho zoo hauv laminated kua nplaum.Cov iav fiber ntau ntim nrog qhov sib nrug me me yog tsawg, thiab cov iav fiber ntau ntim nrog qhov sib txawv loj dua.Qhov sib txawv loj tuaj yeem txo qhov siab ntawm cov kua nplaum ntshiab.

4. Ua kom zoo rau cov txheej txheej hauv ncoo tsim

Rau hnyav tooj liab PCB, vim hais tias cov tooj liab thickness yog tuab, ntxiv rau lub superposition ntawm cov khaubncaws sab nraud povtseg, tooj liab tau nyob rau hauv ib tug loj thickness, thaum drilling, kev sib txhuam ntawm lub laum cov cuab yeej nyob rau hauv lub rooj tsavxwm rau ib ntev lub sij hawm yog ib qho yooj yim los tsim lub laum hnav. , thiab tom qab ntawd cuam tshuam rau qhov zoo ntawm lub qhov phab ntsa, thiab ntxiv rau kev ntseeg siab ntawm cov khoom.Yog li ntawd, nyob rau hauv lub tsim theem, lub puab txheej ntawm cov ntaub ntawv uas tsis yog-functional pads yuav tsum tau tsim kom tsawg li ntau tau, thiab tsis pub tshaj 4 txheej yog pom zoo.

Yog tias tus qauv tsim tso cai, cov ntaub qhwv sab hauv yuav tsum tsim kom loj li sai tau.Cov ntaub qhwv me me yuav ua rau muaj kev ntxhov siab ntau dua hauv cov txheej txheem drilling, thiab cov cua sov ua kom nrawm nrawm hauv cov txheej txheem ua, uas yooj yim ua rau tooj liab lub kaum sab xis ntawm cov ntaub qhwv.Ua kom qhov kev ncua deb ntawm lub puab txheej sab hauv sab hauv thiab lub qhov phab ntsa ntau npaum li qhov tsim tau tso cai.Qhov no tuaj yeem ua rau kom muaj kev nyab xeeb zoo ntawm qhov sib txawv ntawm lub qhov tooj liab thiab cov txheej txheej sab hauv, thiab txo cov teeb meem tshwm sim los ntawm lub qhov phab ntsa zoo, xws li micro-short, CAF tsis ua haujlwm thiab lwm yam.