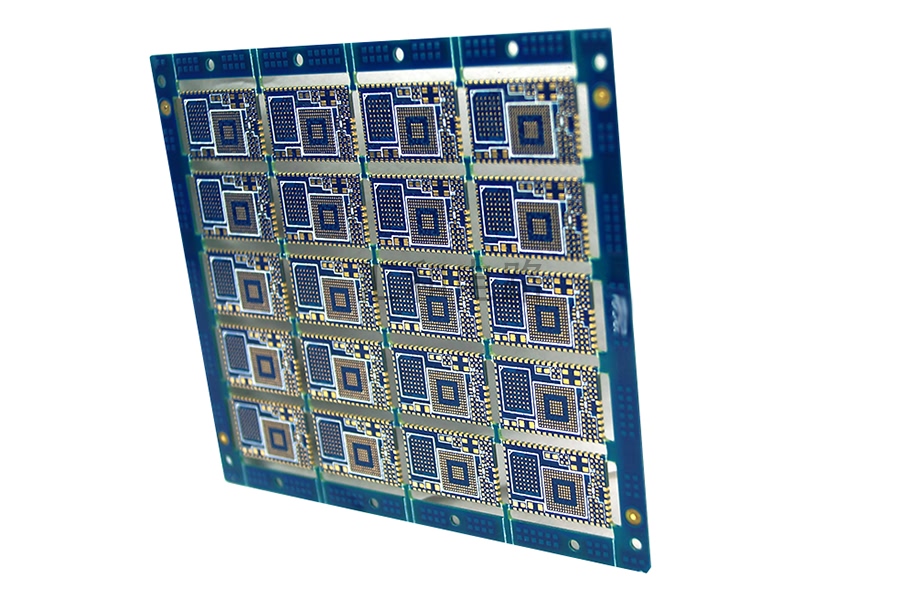

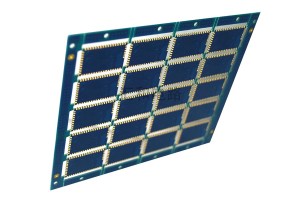

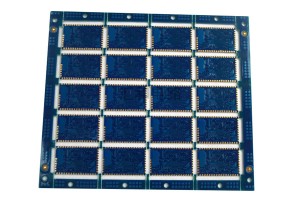

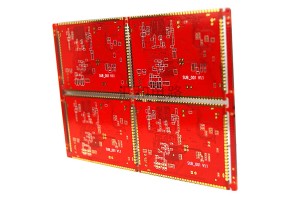

4 Txheej ENIG FR4 Ib Nrab Qhov PCB

Cov Txheej Txheem Metallized Ib Nrab Qhov Ncauj PCB Fabrication

Drilling -- Chemical Copper -- Tag Nrho Cov Phaj Copper -- Duab Hloov -- Graphics Electroplating -- Defilm -- Etching -- Stretch Soldering -- Ib Nrab Qhov Nto Txheej Txheej (zoo li tib lub sij hawm nrog cov Profile).

Lub qhov metallized ib nrab yog txiav nyob rau hauv ib nrab tom qab lub puag ncig lub qhov yog tsim.Nws yog ib qho yooj yim los tshwm sim cov phenomenon ntawm tooj liab hlau residue thiab tooj liab tawv warping nyob rau hauv ib nrab lub qhov, uas cuam tshuam rau kev ua hauj lwm ntawm ib nrab lub qhov thiab ua rau kom txo tau cov khoom ua tau zoo thiab tawm los.Yuav kom kov yeej cov teeb meem saum toj no, nws yuav tsum tau ua raws li cov txheej txheem hauv qab no ntawm metallized semi-orifice PCB:

1. Ua ib nrab qhov ob V hom riam.

2. Nyob rau hauv qhov xyaum thib ob, qhov kev qhia lub qhov yog ntxiv rau ntawm ntug ntawm lub qhov, cov tawv nqaij tooj liab raug tshem tawm ua ntej, thiab cov burr raug txo.Cov grooves yog siv rau drilling kom optimize qhov ceev ntawm ntog.

3. Copper plating ntawm lub substrate, kom ib txheej ntawm tooj liab plating rau ntawm lub qhov phab ntsa ntawm lub round lub qhov nyob rau ntawm ntug ntawm lub phaj.

4. Lub voj voog sab nrauv yog tsim los ntawm compression zaj duab xis, raug thiab kev loj hlob ntawm lub substrate nyob rau hauv lem, thiab ces lub substrate yog plated nrog tooj liab thiab tin ob zaug, thiaj li hais tias cov tooj liab txheej nyob rau hauv lub qhov ntawm phab ntsa ntawm lub puag ncig lub qhov ntawm lub ntug ntawm lub phaj yog thickened thiab tooj liab txheej yog them los ntawm tin txheej nrog anti-corrosion nyhuv;

5. Ib nrab qhov sib sau phaj ntug puag ncig lub qhov txiav hauv ib nrab los ua ib nrab lub qhov;

6. Tshem tawm cov yeeb yaj kiab yuav tshem tawm cov yeeb yaj kiab los tiv thaiv plating hauv cov txheej txheem ntawm zaj duab xis nias;

7. Etch lub substrate, thiab tshem tawm cov exposed tooj liab etching ntawm txheej txheej ntawm lub substrate tom qab tshem tawm cov zaj duab xis; Tin tev Lub substrate yog tev kom lub tin raug tshem tawm ntawm lub semi-perforated phab ntsa thiab cov tooj liab txheej ntawm lub semi- perforated phab ntsa raug nthuav tawm.

8. Tom qab molding, siv daim kab xev liab los lo rau lub tsev daim hlau ua ke, thiab tshaj alkaline etching kab kom tshem tawm burrs

9. Tom qab ob lub tooj liab plating thiab tin plating ntawm lub substrate, lub voj voog ntawm lub npoo ntawm lub phaj yog txiav nyob rau hauv ib nrab los ua ib nrab lub qhov.Vim hais tias cov tooj liab txheej ntawm lub qhov phab ntsa yog them nrog tin txheej, thiab tooj liab txheej ntawm lub qhov phab ntsa yog tag nrho txuas nrog tooj liab txheej ntawm txheej txheej ntawm lub substrate, thiab lub binding quab yuam yog loj, tooj liab txheej ntawm lub qhov. phab ntsa tuaj yeem zam tau zoo thaum txiav, xws li rub tawm lossis qhov tshwm sim ntawm tooj liab warping;

10. Tom qab ua tiav ntawm lub semi-qhov tsim thiab ces tshem tawm cov zaj duab xis, thiab ces etch, tooj liab nto oxidation yuav tsis tshwm sim, zoo zam qhov tshwm sim ntawm tooj liab residue thiab txawm luv luv Circuit Court tshwm sim, txhim kho cov yield ntawm metallized semi-qhov PCB. .

Cov khoom siv Display

PCB Tsis Siv Neeg Plating Kab

PCB PTH kab

PCB LDI

PCB CCD Txhaj Tshuab

Factory Show

PCB Manufacturing Base

Admin Receptionist

Lub Rooj Sib Tham